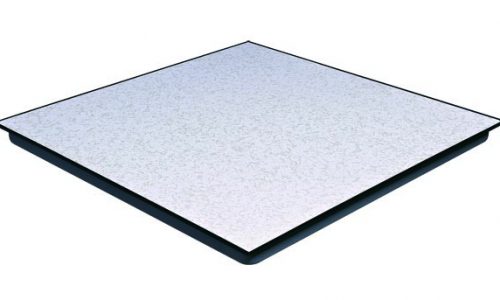

| ANTISTATIC HPL | ||

| 1. | Thickness | 1.2 / 1.5mm |

| 2. | Electrical Surface Resistance | GJB 300 7-97 1×10^6 – 1 x 10 ^10 3. |

| 3. | Static Generation | SJ . T10694-1996=V<100V |

| 4. | Flammable Fire Hazards | GB4609-8-1 FV-1 (<30S) |

| 5. | Abrasion Resistance Test Result | (>350 cycles) 2000 – 2250 cycles |

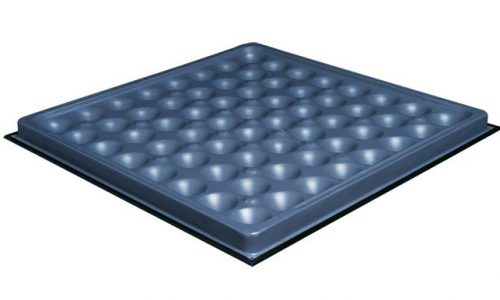

| CONDUCTIVE VINYL | ||||||||||||

| 1. | Thickness | 2.0mm | ||||||||||

| 2. | Electrical Resistance | Between two electrodes 25,000 to 1,000,000 ohms Floor to ground greater than 25,000 oh | ||||||||||

| 3. | Static Generation | Less than 100 volts with conductive footwear per AATCC 134 at 20% relative humidity | ||||||||||

| 4. | Static Decay | 5,000 volts to zero in less than 0.03 seconds | ||||||||||

| 5. | Fire Resistance | Critical Radiant Flux :> 1.08 w/cm2 Flame Spread :< 75 Smoke Density :< 450 |

||||||||||

| 6. | Abrasion Resistance |

|

||||||||||